Loading... Please wait...

Loading... Please wait...Categories

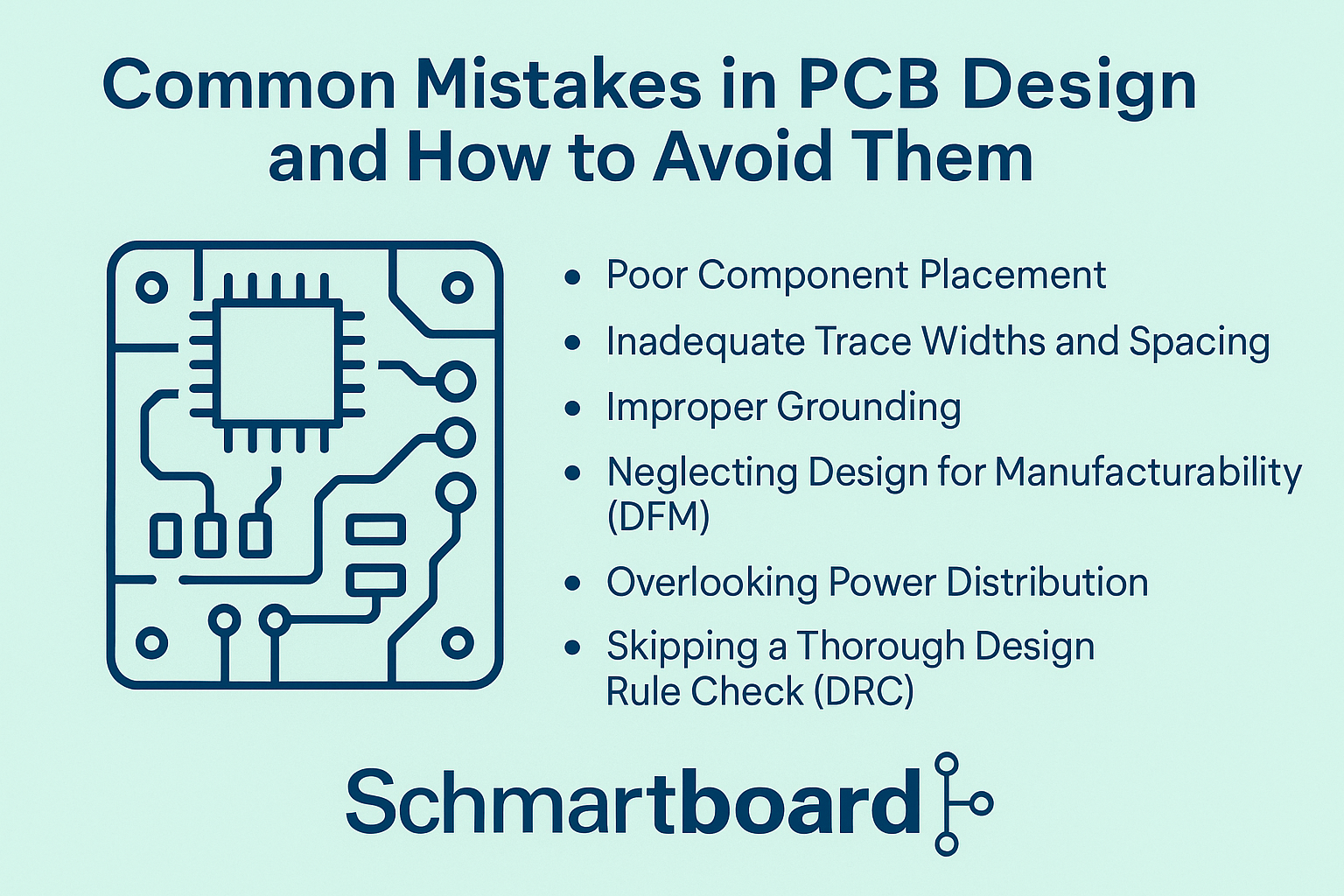

Common Mistakes in PCB Design and How to Avoid Them

Posted by Schmartboard on Jul 29th 2025

Printed Circuit Board (PCB) design is a crucial part of electronics development, and even a small oversight can cause major headaches down the line. Whether you're an experienced engineer or a DIY electronics enthusiast, avoiding common pitfalls in PCB design will save time, reduce costs, and improve your end product. In this blog, we’ll explore some of the most frequent PCB design mistakes — and how you can steer clear of them. Plus, we’ll show how Schmartboard can help simplify and strengthen your PCB prototyping process.

1. Poor Component Placement

Mistake: Placing components without considering signal flow, accessibility, or heat dissipation.

Solution: Plan your layout by grouping components logically. Place critical parts like microcontrollers, power regulators, and oscillators with short, direct trace paths. Keep analog and digital sections separate.

Tip: Schmartboard prototyping solutions come with pre-routed layouts that help guide optimal component placement — a great head start for both beginners and pros.

2. Inadequate Trace Widths and Spacing

Mistake: Using traces that are too thin or placing them too close together, leading to overheating or shorts.

Solution: Use trace width calculators based on current capacity and copper weight. Maintain clearances in accordance with industry standards (IPC-2221 is a good reference).

Tip: Schmartboard’s prototyping boards feature clear and consistent trace sizing and spacing, making it easier to visualize and test proper current handling in your design.

3. Improper Grounding

Mistake: Using a star ground or multiple ground loops, which introduces noise and instability.

Solution: Use a ground plane whenever possible. This ensures low impedance and minimizes EMI (electromagnetic interference).

Tip: Many Schmartboard modules incorporate dedicated ground planes or wide ground traces, promoting a clean and stable design environment for your prototypes.

4. Neglecting Design for Manufacturability (DFM)

Mistake: Creating a design that's hard or expensive to manufacture, such as placing vias under components or using obscure part packages.

Solution: Stick with industry-standard footprints and follow DFM guidelines from your PCB manufacturer. Always double-check footprints and spacing in your design software.

Tip: Schmartboard offers boards designed around commonly used package types, including QFP, SOIC, and QFN, with patented "EZ" soldering technology that simplifies prototype assembly — especially for surface-mount devices (SMDs).

5. Overlooking Power Distribution

Mistake: Power traces that are too long or too narrow, causing voltage drops and instability.

Solution: Use power planes or wide traces for high-current paths. Keep decoupling capacitors close to power pins.

Tip: Schmartboard prototyping boards often include thoughtful power and ground rail layouts that reduce the chances of power integrity issues during development.

6. Skipping a Thorough Design Rule Check (DRC)

Mistake: Failing to run a full DRC before finalizing the design, leading to errors that can only be caught during manufacturing or assembly.

Solution: Always run DRC in your PCB design software. Use ERC (Electrical Rule Check) to validate net connections.

Tip: Even when working on a breadboard or prototype board, tools like Schmartboard reduce error-prone wiring by guiding connections through labeled, pre-routed traces.

Final Thoughts: Schmartboard as Your Prototyping Ally

Avoiding these PCB design mistakes is critical — especially when deadlines and budgets are tight. Tools like Schmartboard provide a structured, reliable platform to develop and test your circuits. With features like:

-

EZ Soldering Technology for SMDs

-

Modular prototyping boards with built-in routing

-

Support for complex ICs and mixed-signal layouts

…Schmartboard takes a lot of guesswork out of prototyping. Whether you're an educator, student, or engineer, their solutions help you move from concept to tested circuit faster and smarter.

Recent Posts

- » Do Inspect Solder Joints Under Magnification for Intermittent Issues

- » Don’t Assume Power Supplies Are Perfectly Clean

- » Do Choose the Right PCB Stack-Up Early to Support Signal Integrity

- » Do Route High-Frequency Signals with Controlled Impedance

- » Don’t Overcrowd the Board — Leave Room for Debugging