Loading... Please wait...

Loading... Please wait...Categories

The Best Tools for Troubleshooting Electronics Projects

Posted by Schmartboard on Jun 14th 2025

Every electronics enthusiast knows the feeling: you’ve spent hours building a circuit, connecting components, and uploading code—only for it to... not work. Whether you're a seasoned engineer or just getting started, troubleshooting is a critical skill in electronics. But even more important than skill is having the right tools in your kit.

Here’s a breakdown of the best tools for diagnosing, fixing, and understanding your electronics projects—so you can get from “why isn’t this working?” to “got it!” faster.

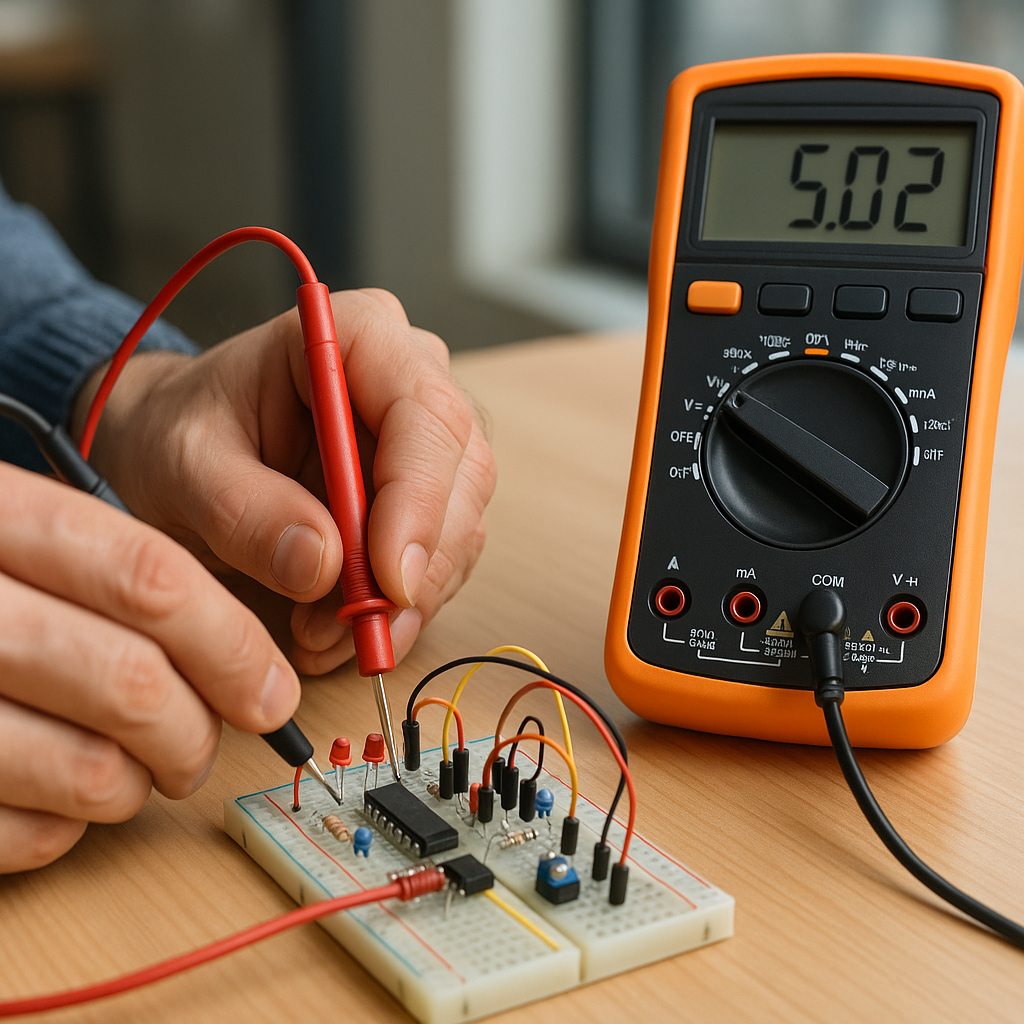

1. Multimeter – Your First Line of Defense

A digital multimeter (DMM) is the go-to tool for electronics troubleshooting. It can measure voltage, current, resistance, and continuity.

What to look for:

-

Auto-ranging capabilities

-

Backlit display

-

Continuity buzzer

-

Safety-rated probes

Tip: When a circuit isn’t powering up, start by measuring voltages at key points to ensure your power supply is working properly.

2. Oscilloscope – See What’s Really Going On

While a multimeter gives you static readings, an oscilloscope shows real-time waveforms. It's essential when working with analog signals, sensors, or high-speed digital lines.

Best for:

-

Diagnosing timing issues

-

Viewing noise or ripple on power lines

-

Verifying communication protocols (like I2C, SPI, UART)

Entry-level recommendation: USB-based oscilloscopes (like Hantek or Digilent) are affordable and great for hobbyists.

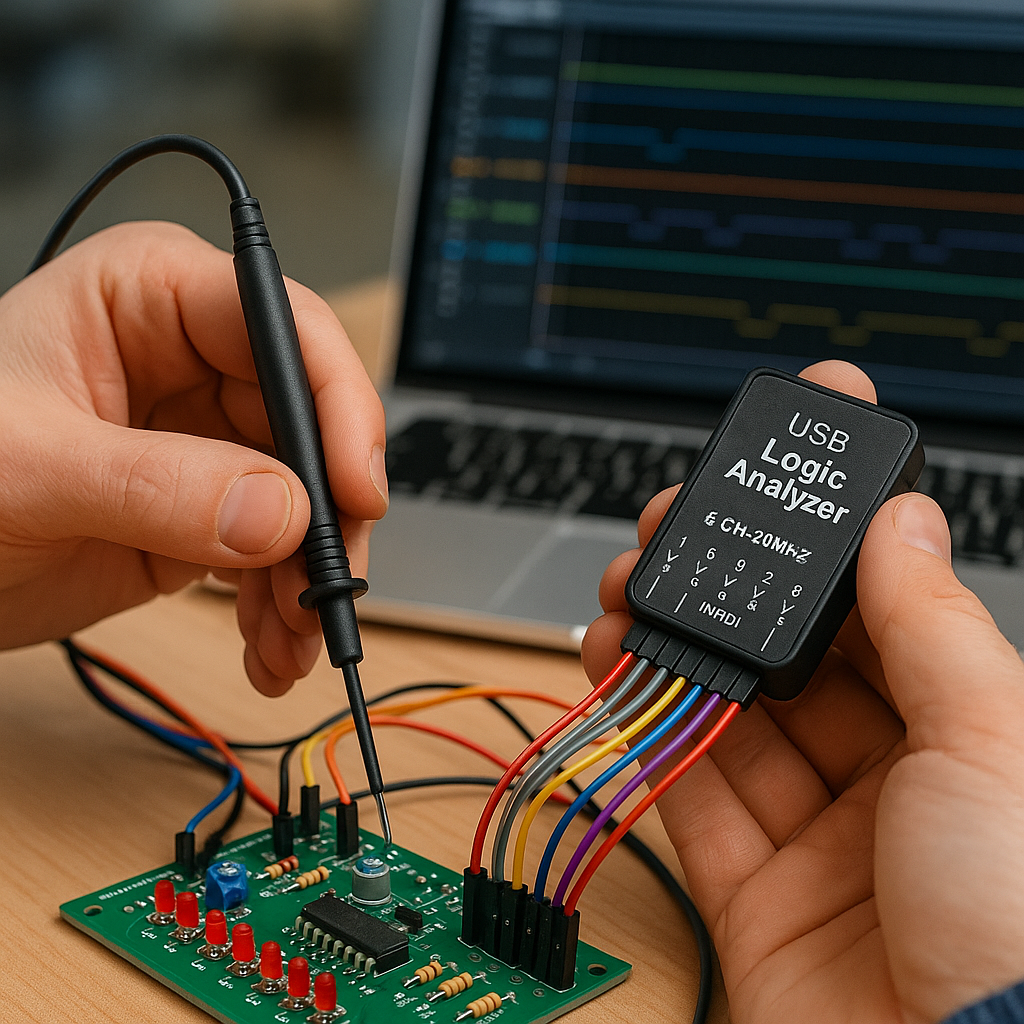

3. Logic Analyzer – Digital Debugging Made Easy

When working with digital circuits, especially microcontrollers or communication buses, a logic analyzer is a lifesaver. It lets you capture and decode digital signals, so you can verify data and pinpoint errors.

Great for:

-

Debugging I2C, SPI, UART

-

Monitoring GPIO states

-

Checking pulse width or timing

Tools like the Saleae Logic or open-source analyzers with Sigrok support offer powerful protocol decoding.

4. SchmartBoard Prototyping Tools – Build & Debug Faster

When prototyping with surface-mount devices (SMDs), it’s easy to make soldering mistakes that are hard to see—let alone fix. SchmartBoard products are designed to make soldering and troubleshooting easier.

Why SchmartBoard?

-

Patented EZ soldering technology simplifies SMD work

-

Adapter boards help integrate ICs and sensors quickly

-

Excellent for repairing or modifying existing circuits

Bonus: Their jumper wire kits and breakout boards make it easy to re-route connections or bypass faulty traces without redoing your entire board.

5. Magnifying Lamp or Microscope – See the Unseen

A surprising number of issues are due to poor solder joints, micro-bridges, or lifted pads—especially with SMDs. A magnifying lamp or USB microscope helps you visually inspect your board without eye strain.

6. Soldering Station – Not Just for Building

A good soldering station is also a key repair tool. Whether you’re fixing bridges, resoldering loose wires, or replacing components, temperature control and fine tips make all the difference.

Recommended features:

-

Adjustable temperature

-

Interchangeable tips

-

Rapid heating

Add solder wick and flux pens to handle most soldering errors with ease.

7. Online Tools & Simulators

Don’t underestimate digital resources. Simulators like LTspice, Falstad, or Tinkercad Circuits let you test ideas before wiring them up. Datasheets, forums (like EEVBlog, Reddit r/electronics), and open-source libraries are also goldmines when you're stuck.

Final Thoughts

Troubleshooting electronics isn’t just about solving problems—it's about learning from them. With the right tools on hand, you’ll not only fix your circuits faster but also gain a deeper understanding of how they work.

Whether you're debugging a blinking LED or diagnosing a flaky microcontroller setup, these tools will give you the visibility, control, and precision you need to move forward with confidence.

Need help with your next project?

Explore SchmartBoard’s prototyping products for reliable, professional-grade tools that make building—and debugging—easier than ever.

Recent Posts

- » Do Inspect Solder Joints Under Magnification for Intermittent Issues

- » Don’t Assume Power Supplies Are Perfectly Clean

- » Do Choose the Right PCB Stack-Up Early to Support Signal Integrity

- » Do Route High-Frequency Signals with Controlled Impedance

- » Don’t Overcrowd the Board — Leave Room for Debugging