Loading... Please wait...

Loading... Please wait...Categories

Choosing Between Soldered and Solderless Connections (and How Schmartboard Simplifies SMD Soldering)

Posted on Apr 6th 2025

When diving into electronics projects—whether you're prototyping, building a hobbyist device, or designing a small production run—one of the key decisions you'll face is choosing between soldered and solderless connections. Each approach has its pros and cons depending on your project's goals, complexity, and need for durability. And when it comes to soldering, especially with surface mount components (SMDs), tools like Schmartboard can make the process dramatically easier—even for beginners.

Soldered Connections

What They Are:

Soldered connections involve joining wires or components by melting solder around them, creating a conductive and durable bond once cooled.

Pros:

-

Strong, permanent electrical connections

-

Ideal for production or long-term projects

-

Compact and neat—especially useful on printed circuit boards (PCBs)

-

Handles vibration and movement better

Cons:

-

Time-consuming to assemble or rework

-

Requires tools: soldering iron, solder, flux, etc.

-

Mistakes are harder to fix (especially with surface mount)

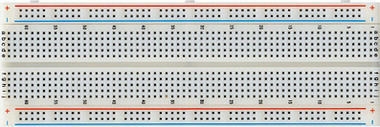

Solderless Connections

What They Are:

Solderless setups use breadboards, jumper wires, or connector systems to create temporary or modular circuits.

Pros:

-

Quick to build and modify

-

Ideal for prototyping and experimentation

-

No tools or heat required

Cons:

-

Can be unreliable over time (loose wires, poor contact)

-

Not suitable for final products or environments with vibration

-

Limited by breadboard compatibility (not ideal for SMDs or high-frequency circuits)

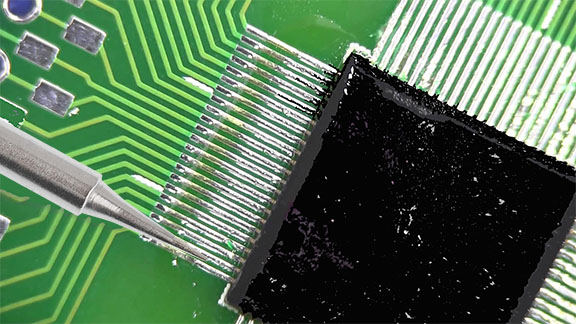

The Challenge with Surface Mount Components

Surface mount devices are becoming more common thanks to their size and performance advantages, but they’re notoriously tricky to solder by hand. Their tiny pins and close spacing are a challenge for even experienced hobbyists.

Enter Schmartboard.

Schmartboard: Making SMD Soldering Easy

Schmartboard offers a line of prototyping boards specifically designed to simplify the soldering of surface mount components. Their patented “EZ” technology features pre-tinned traces with solder channels that guide the solder and component into place as you heat it.

Why It’s a Game-Changer:

-

Beginner-friendly: You don’t need expert soldering skills to succeed.

-

No microscope needed: The grooves guide the solder right to the pads.

-

Time-saving: Far easier than aligning pins manually on a standard PCB.

-

Supports many packages: From SOIC to QFP and beyond.

For those who want the reliability of soldered connections but dread the frustration of surface mount soldering, Schmartboard bridges the gap perfectly.

Which Should You Choose?

| Project Type | Recommendation |

|---|---|

| Fast prototyping/testing | Solderless (Breadboard or connectors) |

| Long-term reliability | Soldered |

| High-vibration environments | Soldered |

| Working with SMDs | Soldered with Schmartboard |

| Educational/Learning | Both, depending on goals |

Final Thoughts

Solderless connections are great for speed and flexibility, but when it comes to durability, performance, and compactness—especially with surface mount components—soldering is the way to go.

If soldering SMDs has been a barrier for you, Schmartboard offers an elegant solution that makes precision soldering accessible to everyone. Whether you're an educator, hobbyist, or engineer, their boards help remove the intimidation from surface mount work—one guided groove at a time.

Have you tried Schmartboard or have a favorite soldering trick? Let us know in the comments!

Recent Posts

- » Do Inspect Solder Joints Under Magnification for Intermittent Issues

- » Don’t Assume Power Supplies Are Perfectly Clean

- » Do Choose the Right PCB Stack-Up Early to Support Signal Integrity

- » Do Route High-Frequency Signals with Controlled Impedance

- » Don’t Overcrowd the Board — Leave Room for Debugging